State Data

Confidence in data for this state:

MODERATELY HIGH

2018 data unless noted.

Definitions

Terms used on this website and in data sets are defined & discussed here.

Biosolids in dewatering bags at a facility near Mount Rushmore. Photo courtesy of SD DANR.

Dewatering bags near Mount Rushmore drain into pipes that feed back to the facility’s headworks. Photo courtesy of SD DANR.

Biosolids drying in Spearfish before going to Gillette, WY for further treatment and beneficial use. Photo courtesy of SD Dept. of Agriculture and Natural Resources (DANR).

State Statistics Dashboard

State Summary

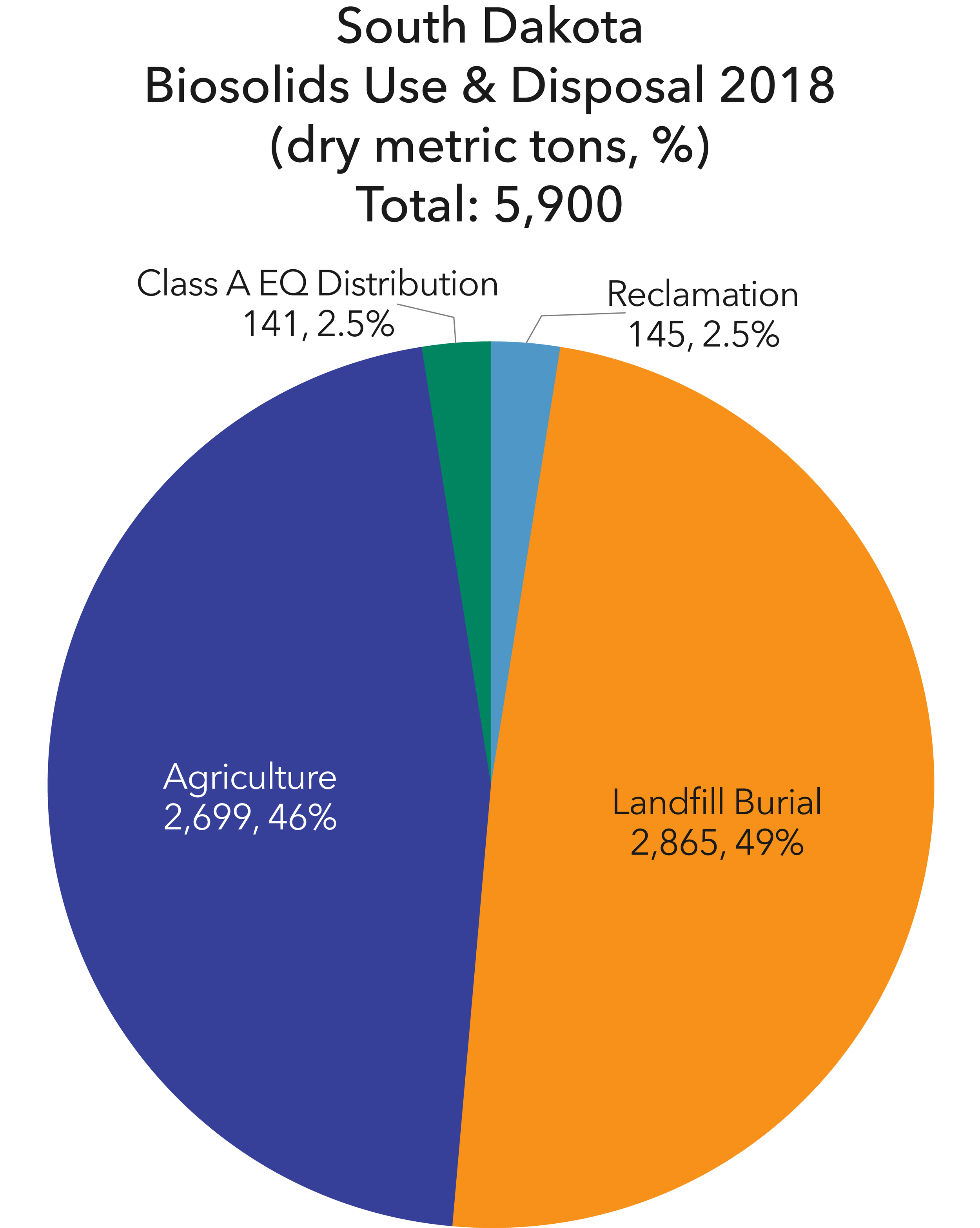

● South Dakota is a sparsely populated state where many municipalities only manage solids (sludge) from wastewater treatment and solids lagoons every few years, usually through land application of Class B biosolids or disposal in landfills.

● Biosolids are regulated by the Department of Agriculture and Natural Resources (DANR), Office of Water, Surface Water division. South Dakota received delegation of the 40 CFR Part 503 biosolids permitting program from the U.S. EPA and has a statewide general permit for biosolids land application. DANR grants individual permits to WRRFs or separate preparers. The state’s requirements for land application go beyond those of Part 503, including setbacks from water bodies and wells, submission of field maps, and public notification during the site-permitting process.

● Septage is also regulated by the DANR Surface Water division. Septage can be hauled to WRRFs or land applied at non-public contact sites. If land applied, septage must meet requirements for pathogen reduction, vector attraction reduction, screening, agronomic loading rate (based on nitrogen), and site restrictions (which depend on septage quality - if lime stabilized, fewer restrictions apply).

● Rapid City’s Water Reclamation Facility treats about 9.5 million gallons per day (MGD) of wastewater and sends its biosolids to the local landfill, where some are composted, along with yard waste and other organics, and sold to the public. In 2018, 141 dry metric tons were composted, and the majority of Rapid City’s biosolids (1,056 dry metric tons) were disposed of in the landfill.

● Sioux Falls – the state’s largest city – treats an average of ~17 MGD and has a program dubbed “SiouxperGrow.” After solids go through anaerobic digestion and storage in lagoons, Class B biosolids from the Water Reclamation Facility (WRF) are land applied on area farms (liquid application) at no cost to farmers. WRF staff carefully test and monitor biosolids and soils, ensuring application rates meet agronomic loading rates and crop needs. Sioux Falls biosolids that are not land applied are disposed of in the regional landfill, for which the city pays ~$36/ton. In 2018, about half of the solids went to landfill and half were land applied. Biogas is captured from the WRF’s anaerobic digesters and used for cogeneration of heat and electricity, producing enough power to cover almost 60% of the facility’s demand. Plans are being made to install a receiving station for fats, oils, and grease (FOG), to boost renewable electricity generation further and meet ~80% of the WRRF’s needs. As Sioux Falls grows, biosolids production has begun to outpace land application capacity. In 2019, Sioux Falls started planning for an upgrade to its process: drying biosolids, producing an EQ product with more options for beneficial use.

● Aberdeen, the 3rd largest community, treats ~4 MGD of wastewater, producing anaerobically-digested Class B biosolids that are land applied on area farms.

● The capital, Pierre (population ~14,000), generates about 1.5 MGD and discharges effluent to the Missouri River. In 2018, its solids were put into its storage lagoon, which is cleaned out every few years.